Do you trust your compliance data? Take control of your aircraft fleet maintenance programs and examine the benefits of WinAir’s maintenance schedule templates

Article includes a YouTube video that provides an overview of WinAir’s maintenance programs and a downloadable document that summarizes the benefits of utilizing maintenance schedule templates—content located at the bottom of this article

(Photo Credit: Airbus EC-120B Colibri helicopters by Ryan Fletcher/Shutterstock.com)

Whether you’re an Operator, a Heliop, an MRO, or a CAMO, having access to data that you can trust is mission-critical. When compliance is properly maintained, system data is accurate, safety risks are mitigated, and AOG situations are minimized. When it is not properly maintained, operations can encounter a variety of issues, which if identified during an audit, could result in the grounding of aircraft or the suspension of an aircraft operator’s certificate (AOC).

WinAir uses a template approach to managing aircraft maintenance schedules, which increases the accuracy of reporting and ensures operational compliance with industry standards and regulations. Operations using WinAir can create templates in-house or they can take advantage of the skills, expertise, and first-hand knowledge of WinAir’s Aircraft Services team to develop them to exact manufacturer maintenance specifications on their behalf. This service can be a significant benefit for any operation that is short on time or lacking the resources to build aircraft templates.

With an aircraft template, operations simply apply the appropriate tasks and components when adding new aircraft to the system. Not only does this process follow industry best practices, it safeguards against the introduction of inaccurate data, which means that you will always remain compliant. Using an aircraft template is also a cost-effective approach to managing maintenance schedule programs, as you can continue to use the same aircraft template as you incorporate new aircraft of that type into your fleet.

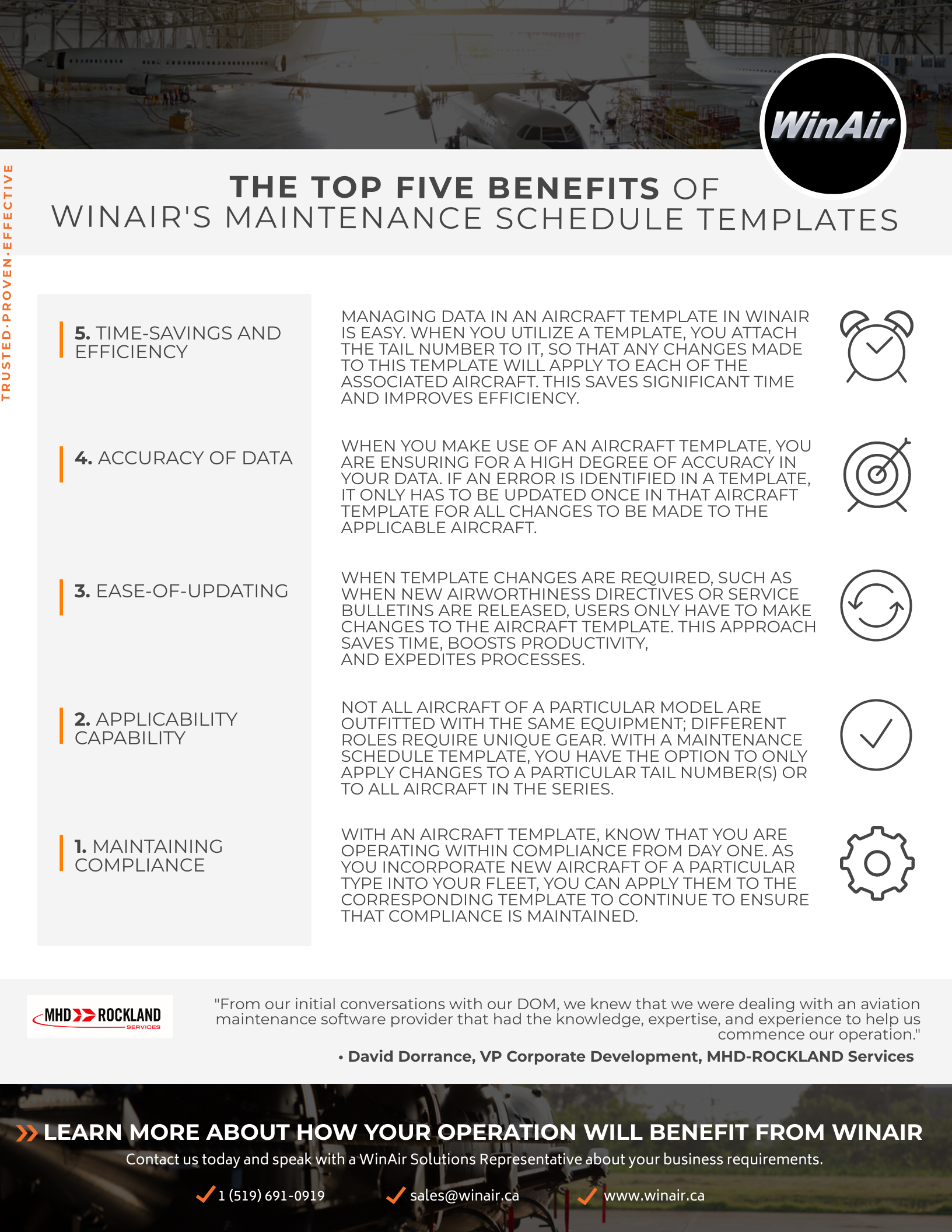

Here are the top five benefits of WinAir’s maintenance schedule templates:

(A Keewatin Air Beechcraft Super King Air awaits the next mission – © Keewatin Air)

5. Time-savings and Efficiency

Managing data in an aircraft template in WinAir is easy. When you utilize a template, you attach the tail number to it, so that any changes made to this template will apply to each of the associated aircraft. For instance, if your operation flies the Beechcraft Super King Air and are using an aircraft template, then newly acquired aircraft of this model can be easily imported into WinAir by selecting the tasks, components, ADs (Airworthiness Directives), and SBs (Service Bulletins) that apply to the particular tail number.

If your operation is forecasting an expansion, then investing in an aircraft template could be a practical approach to managing fleet maintenance. Since you know that you will be using this template for each successive aircraft of this type that is incorporated into your fleet, acquiring an aircraft template is a win-win situation in terms of the present tense and for the future of your operation. Taking advantage of WinAir’s Aircraft Services will allow for tremendous time-saving while integrating new aircraft into your fleet.

4. Accuracy of Data

When you make use of an aircraft template, you are ensuring a high degree of accuracy in your data. If an error is identified in an aircraft template, it only has to be updated once in that template for all changes to be made to the applicable aircraft. Let’s say your operation commands a fleet Airbus AS350 helicopters. If you find an interval that is incorrect in this template, rectifying the situation only requires that you make a simple amendment to this template. This change will cascade down and update the data for all aircraft that correspond with this template.

When you consider the fact that the Airbus AS350B3 aircraft template has 140 components and 1023 tasks (with 16 different checks, 279 tasks for ADs and 17 tasks for SBs), you can begin to realize how massive an undertaking it can be to update numerous copies of a particular aircraft’s maintenance schedule. Plus, if you are working with multiple copies of an aircraft, there is always the potential to carry over past mistakes. You will never duplicate past mistakes with an aircraft template because you will never copy it. With one template, you can maintain data for all aircraft of a specific type.

3. Ease-of-updating

With an aircraft template, you can easily update information, which will apply to the entire series of aircraft associated with that template. When this template is created by WinAir, you know that you are working with accurate data from the start. When new ADs or SBs are released, users only have to make changes to the aircraft template. This approach saves time, boosts productivity, and expedites processes, as you do not have to make updates to multiple copies of an aircraft, but only to a single template.

Depending on the scenario, operators may be required to make multiple updates to a template. This is especially the case when considering the number of ADs and SBs that must be completed to convert aircraft to a new role. Take the example of the Airbus AS332 L1 Super Puma, a mainstay helicopter in the offshore oil and gas industry that is now being converted by helicopter operations into a utility/firefighting aircraft. Transforming this aircraft from its prior capabilities to this new role requires the successful completion of a variety of ADs and SBs. Without a template, all information would have to be updated per each aircraft, making these changes an arduous task.

We recently updated an AS332 L1 template for a client. It had 211 components and 1786 tasks associated with it. Within that, there were 23 different checks, 273 tasks for AD’s, and 55 tasks for SB’s. This template has 15 zones with 192 positions. If these changes had to be made to maintenance schedules for each aircraft, it would have taken an exceptional amount of time. However, with a template, updates can be done swiftly and smoothly.

2. Applicability Capability

Not all aircraft from a particular model are outfitted with the same equipment; different roles require unique gear. To demonstrate this point, consider the many uses of an Airbus H145 helicopter at a law enforcement agency, search and rescue (SAR) operation, or aeromedical operation. While a company operating with this aircraft in their fleet may outfit some of these helicopters with strobe lights, hoists, and cameras, this may not be the case for all of helicopters in the series. This means that you need a way to differentiate aircraft of a specific type that have certain equipment from those that do not.

With a maintenance schedule template, you don’t have to use multiple copies of a maintenance schedule to account for these types of variances. You have the option to only apply changes to a particular aircraft tail number(s) or you can apply changes to all aircraft in the series. This offers operations the flexibility that they require to manage variances between aircraft of the same type.

1. Maintaining Compliance

When you decide to use an aircraft template, you can rest assured knowing that you’re using the same accurate aircraft template and operating within compliance from day one. As you take on new aircraft and apply them to this template, you can continue to ensure that compliance is maintained. If changes that affect all aircraft in the series are made to the template, you will always remain within compliance.

With a template, compliance for even the most complex aircraft can be managed with ease. Consider how monumental a task it would be to accurately manage maintenance schedules and maintain compliance for a fleet comprised of complex aircraft like the Viking Air CL-415, the Lockheed L-285D (the civilian variant of the P-3 Orion), or the Boeing 737-700 without an aircraft template. Updating information, while simultaneously ensuring compliance, would be a grandiose and tiresome task. A template, however, makes maintaining compliance simple.

Ensure Compliance from Day One with Maintenance Schedule Templates

(CL-415 maintenance at an aircraft hangar)

With an aircraft template, your aviation operation has the opportunity to start with accurate data from the get-go. This approach makes compliance straightforward from the beginning and easy to maintain as your operation expands and adds new aircraft. Any changes only have to be made once by updating the template, which saves time, streamlines and expedites processes, and ensures compliance.

If your operation requires assistance with building or importing aircraft data into these templates in WinAir, then our Aircraft Services team is here to lend a helping hand. We have the industry experience that is required to build templates efficiently, effectively, and in an accelerated timeframe. Regardless of aircraft type or complexity, our team has the necessary skills to complete this task for you and with precision.

Are you interested in learning more about WinAir and our Maintenance Schedule Templates? If so, then download our Top Five Benefits of WinAir’s Maintenance Schedule Templates Summary Sheet and then contact us today to book a time to discuss your operation’s unique needs!

About WinAir:

Based in London, Ontario, Canada, WinAir has 30 years of experience as a leader in aviation management software. Companies rely on WinAir to efficiently and effectively track and manage aircraft maintenance and inventory control. WinAir is proud to lay claim to hundreds of installations at aviation-specific organizations worldwide. From airlines to heli-ops, law enforcement agencies, oil industry suppliers, MROs, CAMOs, medical evacuation response teams and more, businesses using WinAir regard the solution as a necessary component to the successful management of their fleet maintenance programs.